In fast-paced industrial growth, healthcare and distribution environments, floor space is prime assets and keeping operational speed ROI is critical. The challenge lies in storing more items, retrieving them faster and managing inventory with flawless accuracy all within a shrinking footprint. This is where the Statfield Vertical Carousel, exemplified by our advanced Instamat series, delivers a transformative solution.

Far more than just shelving, a Vertical Storage Carousel is a high-density Automated Storage and Retrieval System (AS/RS) that brings the inventory to the operator. By rotating vertically within a compact column, it eliminates wasted time walking, searching, and reaching. For businesses across Pune, Mumbai, Bengaluru, Chennai, Hyderabad and all over India looking to optimize their operations, the Statfield Vertical Carousel is the engineered answer to space constraints and inefficiency.

What is a Statfield Vertical Carousel?

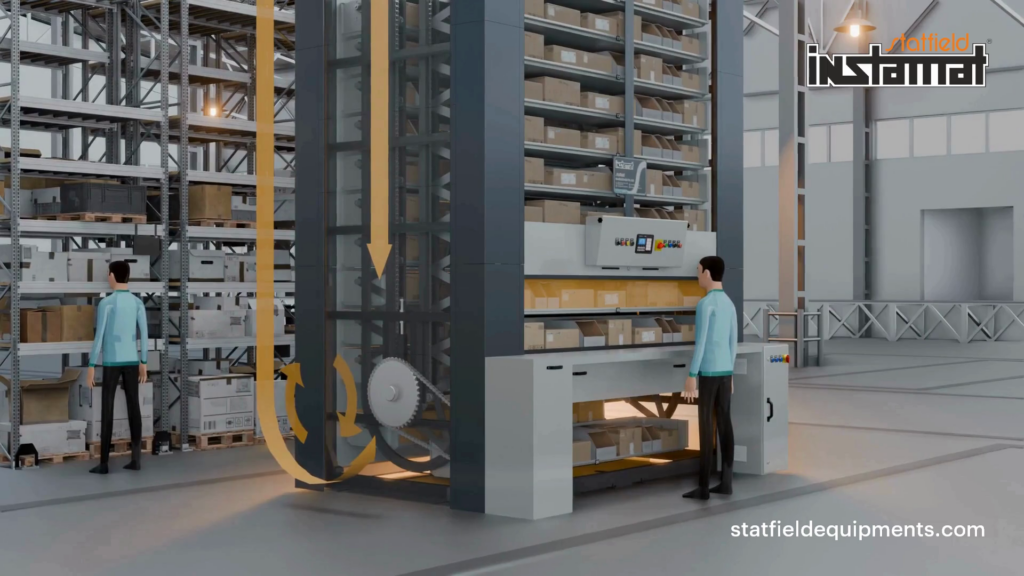

Imagine a ferris wheel for your inventory. The Statfield Vertical Storage Carousel consists of a series of carriers (bins, trays, or shelves) mounted on a vertical rotating frame. Through a simple interface, an operator requests an item. The system automatically rotates to bring the required carrier to an ergonomically positioned access window, presenting items at waist height.

This is the core principle of our Instamat system, a fully automated, software-driven storage unit that maximizes your facility’s cubic volume, turning vertical air space into secure, accessible storage.

Key Benefits: Transforming Storage into a Strategic Advantage

Inside the Technology: The Statfield Instamat Advantage

As a leading manufacturer, Statfield designs the Vertical Carousel with precision, reliability and integration in mind. The Instamat system is built around several core components:

- Robust Construction: Heavy-duty steel frame and carriers designed for long-term, high-cycle use with significant load capacity.

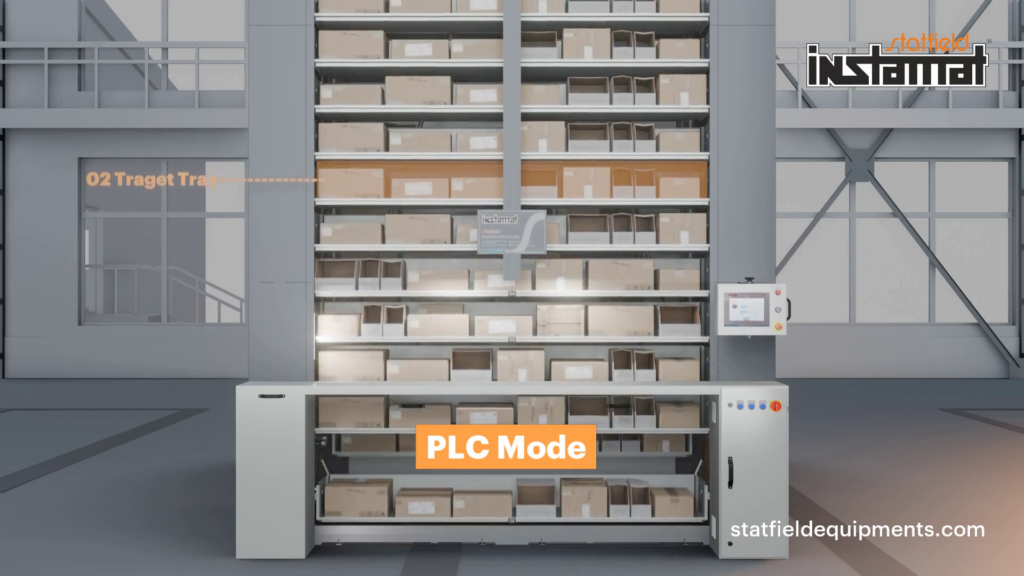

- Intelligent Control System: A user-friendly PLC (Programmable Logic Controller) interface allows for easy item retrieval, inventory management and system reporting. Compatible with ERP and WMS software.

- Advanced Pick-to-Light & Scanning: Optional LED light bars and integrated barcode scanners guide the operator to the exact item and quantity, ensuring error-proof picking.

- Flexible Carrier Options: Configurable bins, drawers or shelves to accommodate everything from small electronic components and pharmaceutical packs to tools and maintenance kits.

- Customizable Configurations: Available in various heights, widths and carrier pitches to perfectly match your ceiling height, space and item dimensions.

Industry Applications: Where the Vertical Carousel Excels

The versatility of the Statfield Vertical Storage Carousel makes it indispensable across sectors:

- Manufacturing & MRO: Store and manage tools, consumables, and critical spare parts for assembly lines and maintenance, reducing machine downtime.

- Healthcare & Hospital Pharmacy: Secure, track, and quickly dispense medications, surgical kits, and supplies with full audit trails.

- Aerospace & Defense: Manage high-value, sensitive components and kits in a controlled, accountable environment.

- Distribution & Order Fulfillment: Handle high-SKU, pick-intensive operations for e-commerce, electronics, and parts distribution.

- Libraries & Archives: Automate the storage and retrieval of media, documents, and special collections.

Ready to maximize your space and efficiency? The Statfield Vertical Carousel is more than storage it’s a strategic productivity engine. Contact our automation experts today to schedule a consultation and discover how our Instamat system can be customized to drive precision, speed, and savings in your operation.