Electrostatic Painting (Automatic)

Electrostatic painting for high volume production

Automatic electrostatic liquid painting is a process that uses specialized equipment to apply liquid coatings to a variety of surfaces in a highly efficient and automated manner. The process typically involves the use of a conveyor system that moves parts through a series of stages, including pre-treatment, coating application, curing, and cooling.

Disc Applicator

This is used for painting of articles on conveyorised lines. Pre – charged paint is fed to disc rotating at high speed, imparting centrifugal force. This causes atomization of paint. The paint particles are negatively charged and deposited on the article due to Electrostatic effect. Transfer efficiency is very high and may reach 90%.

System Components:

- An electromechanical reciprocator with remotely controlled speed, stroke & zone control.

- Applicator.

- Paint feeding system.

- Paint charging unit.

- Control console.

Bell Applicator

This paint applicator can be used for painting large work pieces. The paint is fed to bell shaped applicator rotating at high speed (6000 rpm). The paint particles are atomized due to high rotation speed. The paint particles are negatively charged (at 100kV) and these follow the spray pattern generated due to the air shower and deposit on the article. Transfer efficiency is very high and may reach 90%.

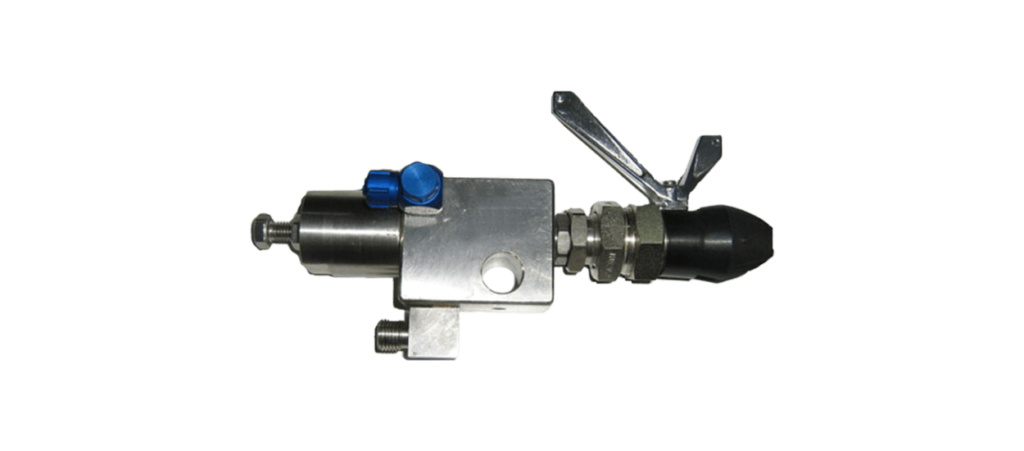

Auto Electrostatic Spray Machine

Auto electrostatic spray machine is ideal for mass production articles where paint consumption is very high. The machine can be mounted on reciprocators.