Overhead Chain Conveyor

Overhead Chain Conveyor for a variety of material handling and transfer tasks

At Statfield’s material handling division, we believe in “Grasp. Think. Solve.” approach. Every enquiry is first analyzed by our engineers to understand customer’s need. Designs are evolved after understanding existing and projected material handling criteria & with advanced manufacturing set up; ideas are transformed into reality with perfection. We conduct in-house overhead chain conveyor trials, before delivery under simulated conditions. Though experience suggests that our product seldom needs service and spares, we have a team of service engineers and a wide dealer network for support should such need arise.

Types of Overhead Chain Conveyors

Statfield overhead chain conveyors are use to move products through processing such as spray painting, dip painting, plating, e-coating, powder coating, sandblasting and cleaning. We provides unique overhead conveyor systems for easy transportation of material from one place to another. Our overhead chain conveyor is a closed system with a roller chain running inside the rails. Load hang on the suspension points on the chain. Check out the following types of overhead chain conveyors.

- Free Rail

- Aerorail

- Transrail

- Megarail

- Power and Free conveyor

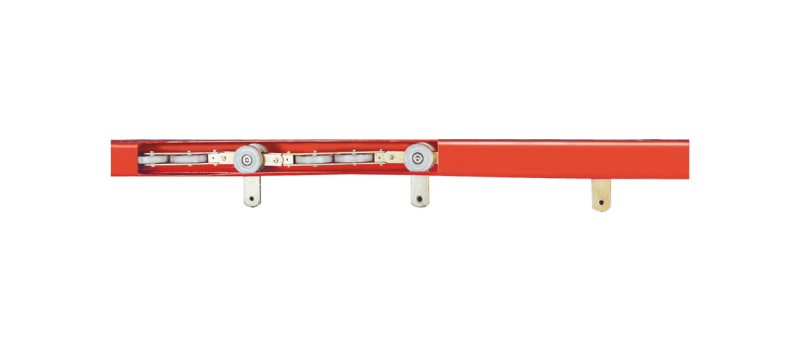

Free Rail

This is the best & most inexpensive choice for transportation of articles to various Locations with a facility to select route, raise, Lower, tilt, queue or wait. Free trolleys carrying weights up to 80 Kg. or 160 Kg. are pulled manually through and enclosed track.

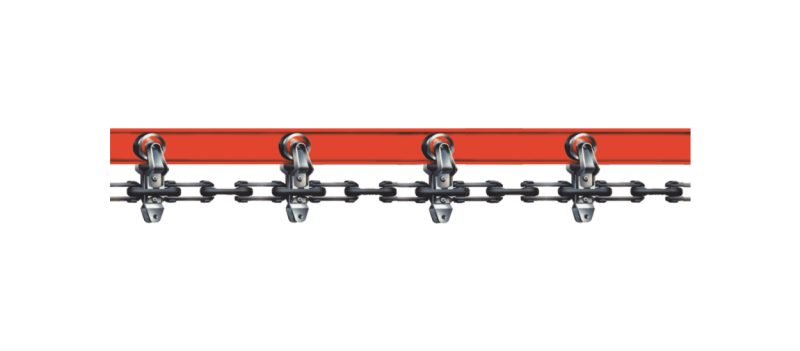

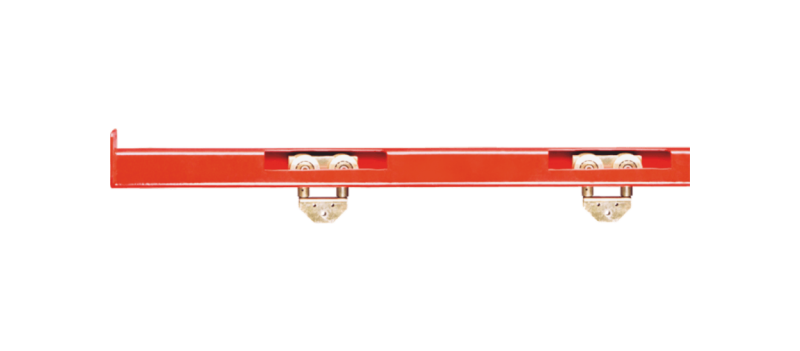

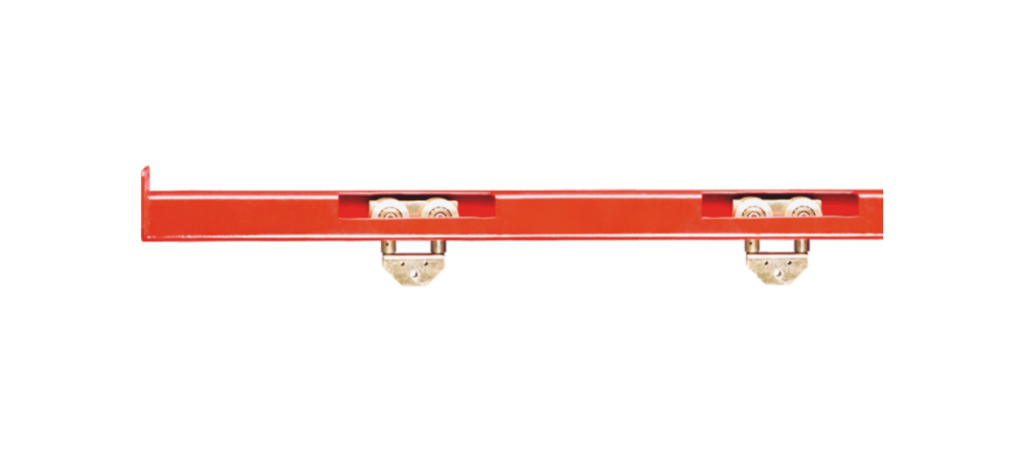

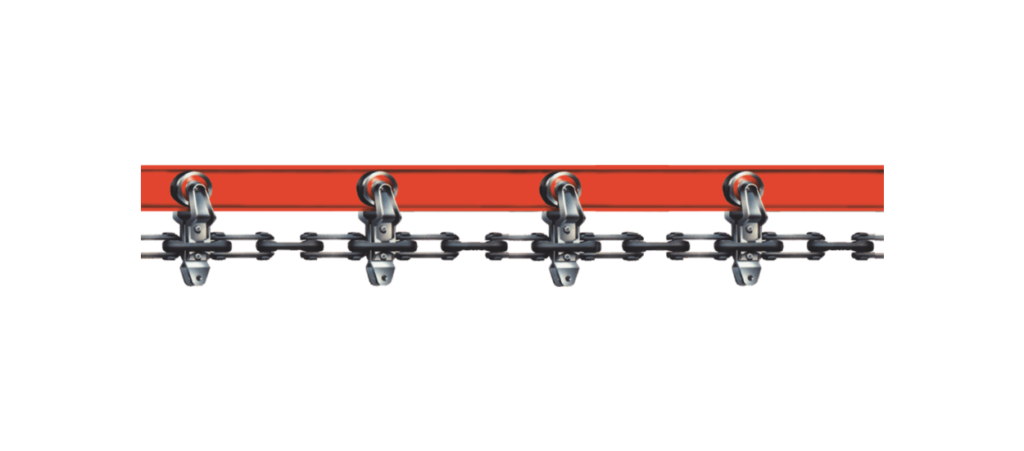

Aerorail

The sophisticated form of overhead chain conveyor with a completely enclosed chain. This medium duty conveyor is mainly used for continuous conveying of material from one point to another, carrying the material through a process station.

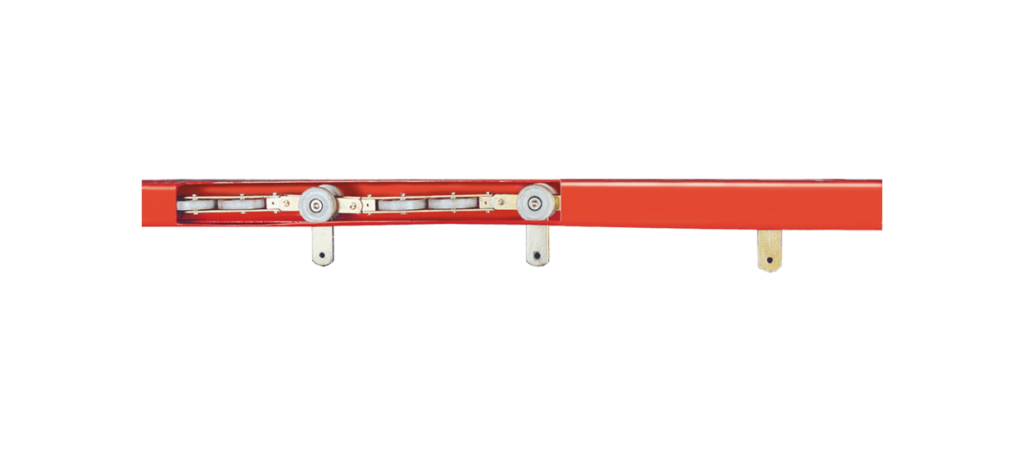

Transrail

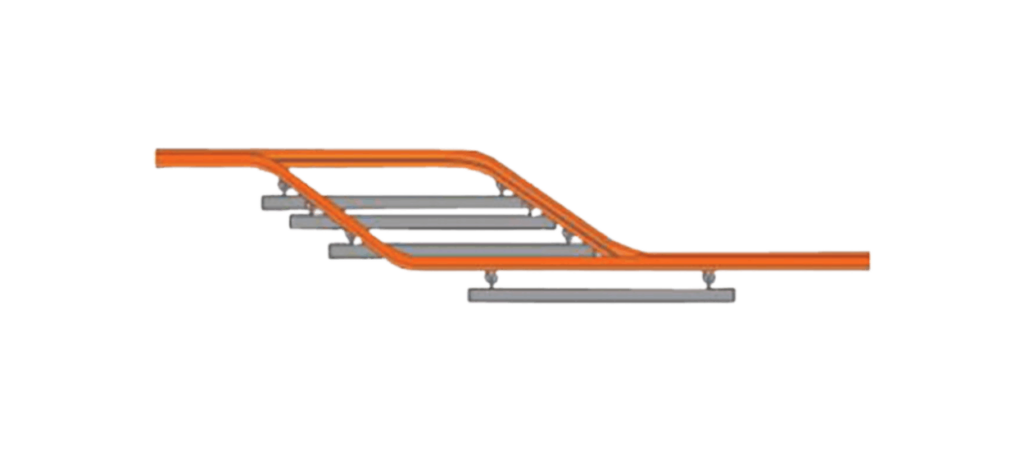

Conveyor with totally flexible handling. The upper track carries powered chain with trolleys on lower track. Trolley can move with main chain or can be stopped / diverted or dropped vertically & can re-enter the main line at any Location.

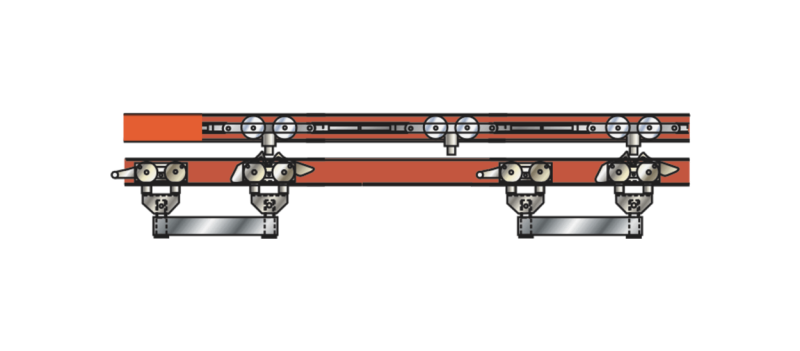

Megarail

Conveyor with totally flexible handling. The upper track carries powered chain with trolleys on lower track. Trolley can move with main chain or can be stopped / diverted or dropped vertically & can re-enter the main line at any Location.

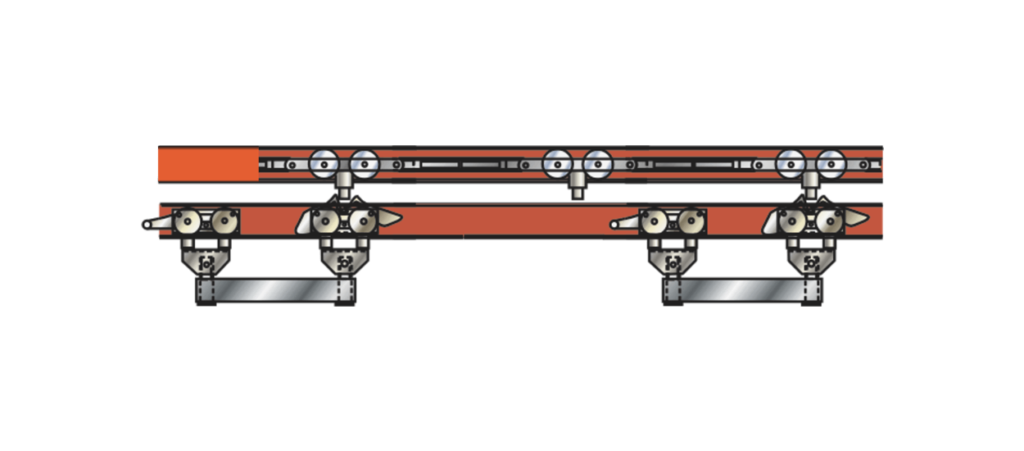

Power and Free conveyor

271- Power & Free conveyor consists of twin tracks arranged one above another. Upper track carries a continuously moving chain; while the lower track consists of free moving push-pawl trolleys for engaging and disengaging. Features

Features

Closed Tracks

Appropriate guide arrangement to keep chains dust proof

Caterpillar Type Positive Transmission Drive Unit

for minimum power consumption and lesser maintenance

Auto lubrication unit

automatic drop type controlled lubrication unit

- Automatic jig tilting machine for Tea industry

- Crate loading / unloading for food processing industry

- Material handling and transfer system

Frequently Asked Questions