Powder Coating Booth / Multicyclone / Filter

Powder Coating Booth / Multicyclone / Filters - Specialised Equipment for Powder Coating process plant

End-to-End solution for all your powder coating requirements. At Statfield we not only provide Powder coating applicators and machine but also provide booth chambers, multi-cyclone for effective powder recovery, and post filters to stop the powder from entering into breathing air.

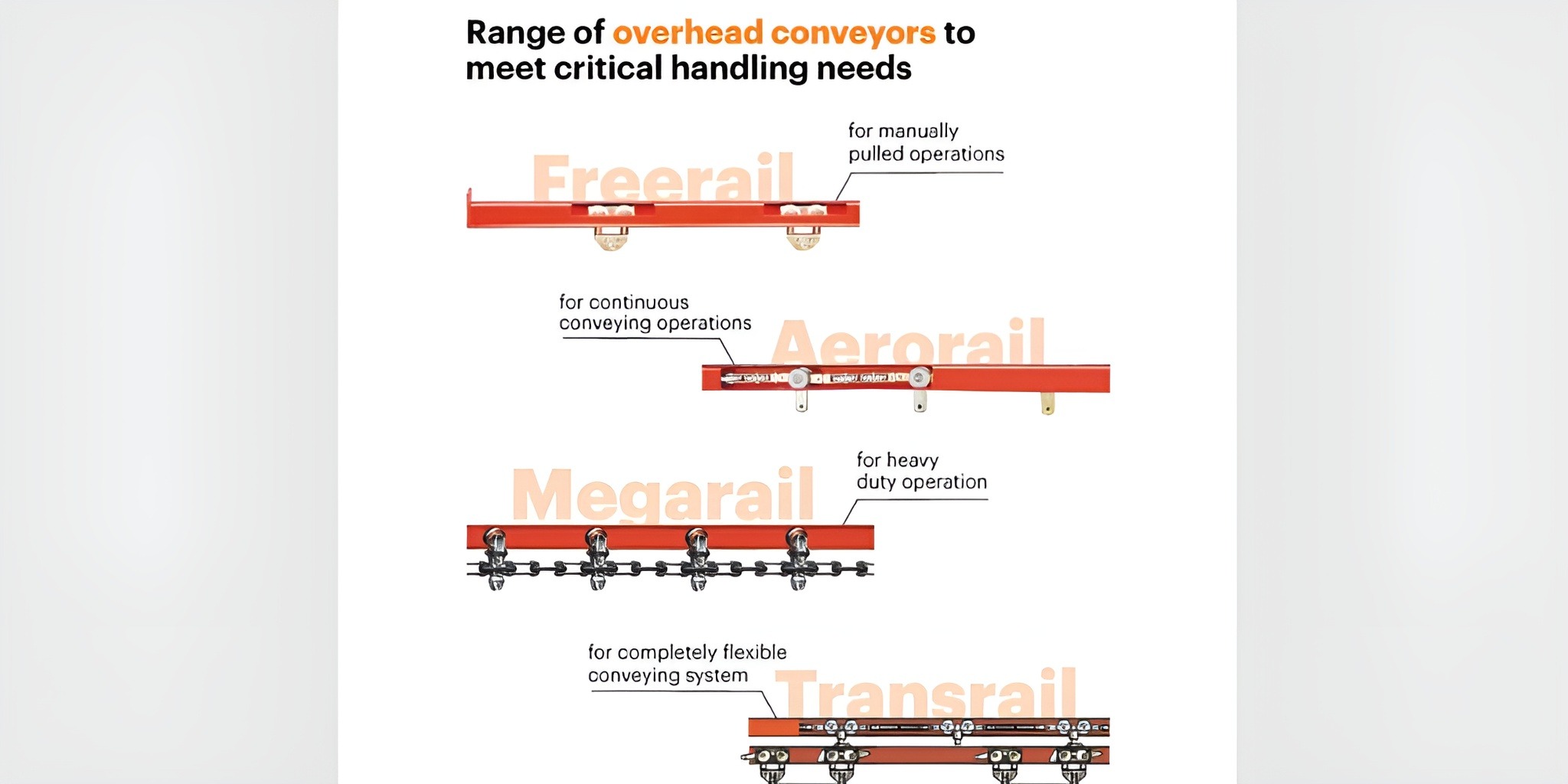

- Modular Multicyclone

- Powder Coating Booth

- Post Filter

- Integration Concept

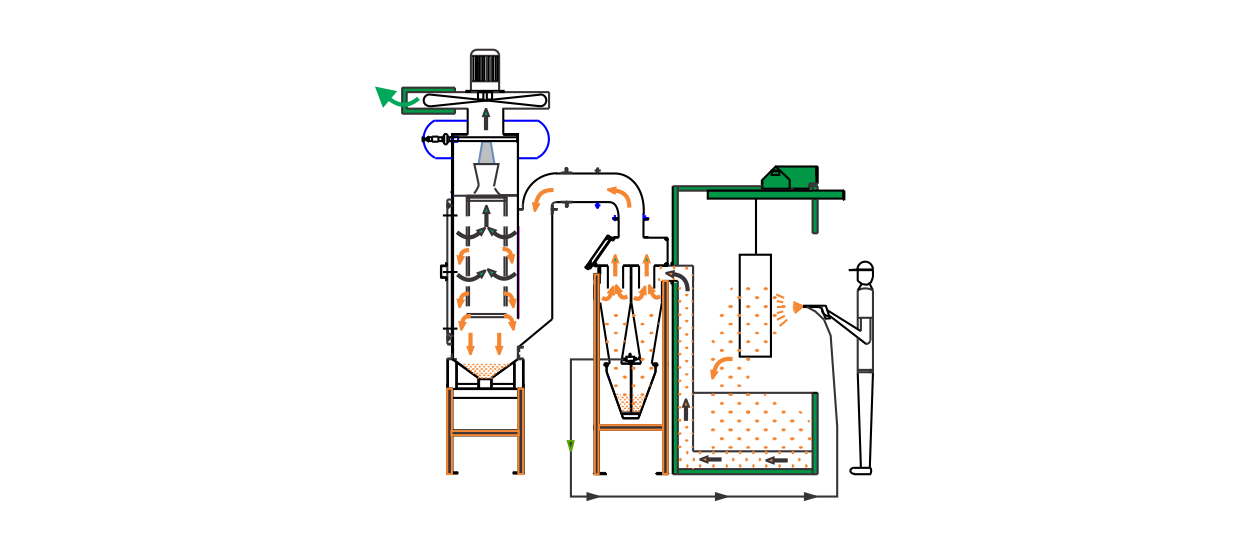

Moduler Multicyclone

Guaranteed efficiency of 98.5 % with a very long life gives the Multicyclone an edge over other powder recovery systems. The high velocity of powder in the multicyclone reduces powder sticking, so cleaning time is negligible.

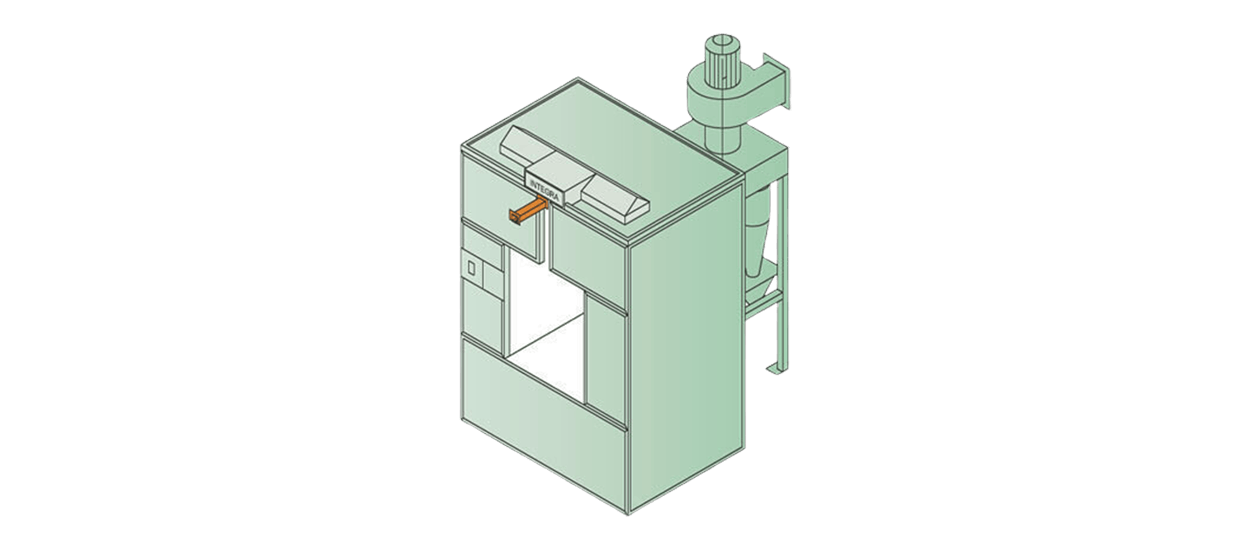

Powder Coating Booth

These types of booths consist of square chamber, multicyclone with blower, motor & bin. Each component of the booth contributes to ensure efficient and optimized powder coating process.

The carbon steel powder coated spray chamber with the multi-cyclone recovery gives almost 100 % powder utilization. It is maintenance free and has a very long life. The powder booth is easy to clean, resulting in a quick colour change and is safe to operate. No powder spillage out of the booth and maximum recovery through the multi-cyclone results in desired pollution control.

Different Models:

Depending upon size of the article, coating requirements, material handling requirements statfield has designed some standard models. Customized booth design is also done for any non standard or specific focus requirements.

Post Filter

98.5% efficiency of the Multicyclone helps in maximum utilization of chargeable powder. But to comply with Pollution Control Laws, the 1.5% powder fines are required to be arrested. The post filter arrests this powder and gives out breathable air.

A number of filter cartridges are mounted inside the sealed metallic chamber. The air enters the chamber and the filteration occurs ‘outside in’. Periodic purge removes the powder and clean the cartridge. Clean air is given out through the blower outlet.

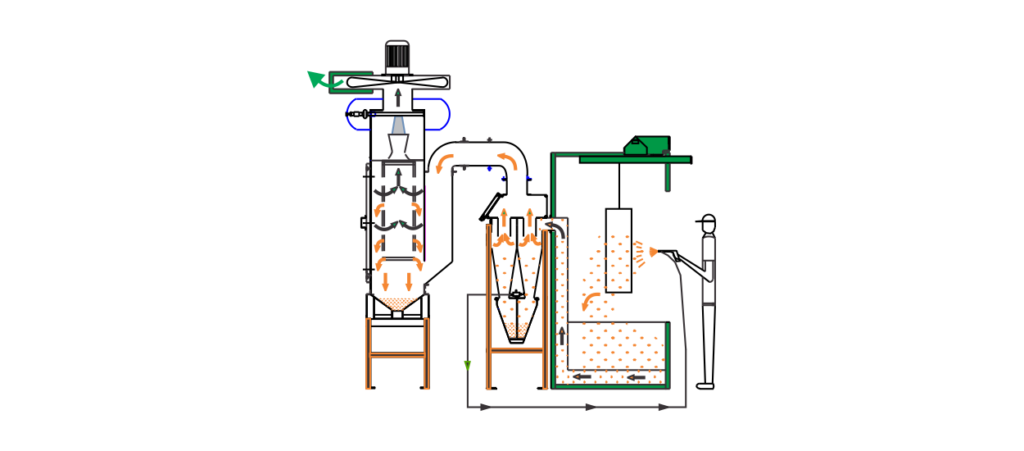

Integration Concept

Booth – when integrated with Equipment and post filter gives:

- Automatic mixing of fresh & recovered powder.

- Automatic feeding of powder to spray equipment.

- Automatic on-line sieving.

- Prevention of entry of fines in atmosphere.

Frequently Asked Questions

A powder coating booth is an engineered enclosure designed to safely apply powder paint to metal objects while containing overspray and collecting reclaimable powder for reuse.

Booths prevent the spread of powder to other plant areas, support a clean working environment, and maximize powder reuse.

Options include cartridge batch booths, conveyor/pass-through booths, lab booths, spray-to-waste booths, and advanced multicyclone booths for fast color changes.

Efficient airflow ensures powder containment, filtration modules reclaim excess powder. Most include features like grounding, explosion-proof design, and customizable sizes.

Clean after each color change and perform a deep cleaning of filters and interior at least weekly, following manufacturer recommendations for filter replacement and seasoning.

A Modular Multicyclone is a pre-filtration device for industrial and water treatment applications. It uses centrifugal force within multiple hydro-cyclones to separate sediment and particles from water, with no moving parts or filter media.

- Captures up to 80% of incoming dirt or sediment before it reaches the main filter, reducing maintenance and extending the life of downstream filtration systems.

- Simple to clean just open the purge valve; no filter cartridges to remove.

- No moving parts, so it’s low maintenance and highly reliable.

It effectively removes particles in the 10–100 micron range, with especially high efficiency (up to 90%) for particles between 40–60 microns.

Applications include powder coating pre-filtration, pool and aquaculture water systems, and various other industrial processes where fine particulate removal is critical.

Generally, it causes minimal pressure loss, but correct sizing and installation are important for optimal flow.

A post filter is a secondary or final-stage filter designed to capture ultrafine particles or contaminants before air or fluid is discharged or recirculated, ensuring maximum purity.

It helps meet environmental, safety and quality standards by capturing particles that other filtration stages may miss vital in powder coating to prevent contamination and maintain air quality.